Our plastic magnets (PLAMAG) are used in a wide range of things in our daily lives such as automobiles, home appliances, OA equipment, housing equipment, etc.

TESLAM is a manufacturer and distributor of magnets.

There are many different types of magnets,

but the magnets we make have the following characteristics.

Flexible for complex shapes

High dimensional accuracy

Excellent shock-resistance

Light weight

Integral molding of different materials

Short Lead-time

Prototype to mass-production: We propose tailor-made magnets in accordance with the customer's requirements, which we can make prototypes to mass-production.

- Material optimization: Optimize forming dies and magnets based on our magnetic fields analysis.

- Pursuit of operational efficiency: Reducing processes for better and efficient operation, by molding in one piece with shafts, pressed and resin parts for greater precision.

- Lightweight: With a specific gravity of 3.2-5.4 g/cm3, lighter than sintered magnets.

- High precision: Dimensional accuracy as high as ±0.02 mm for the most demanding applications.

- Complex shapes: As the magnets are produced by injection molding, complex shapes are possible.

- Shock-resistance: Higher elasticity and impact resistance, than sintered magnets.

- Size capability: Ring-shaped magnets with a diameter of 260 mm can be manufactured based on our track record.

- Performance: Heat resistance up to 240℃, water and corrosion resistant specification are also available.

- Our Plants: The products are manufactured and delivered worldwide from our 3 plants in Asia, which are Nagano Plant, Okayama Plant in Japan, and Shenzhen Plant in China.

Our merchandise are plastic magnets (plastic mags) or as they are called bonded magnets and other products such as composite molded products and environmentally friendly magnetic powders.

Rubber mugs

Rubber mugs are generally formed in sheet form and punched out, but they may be manufactured by injection molding to improve yield and reduce costs.

Binders are flexible plastic mags such as EEA as well as PVC.

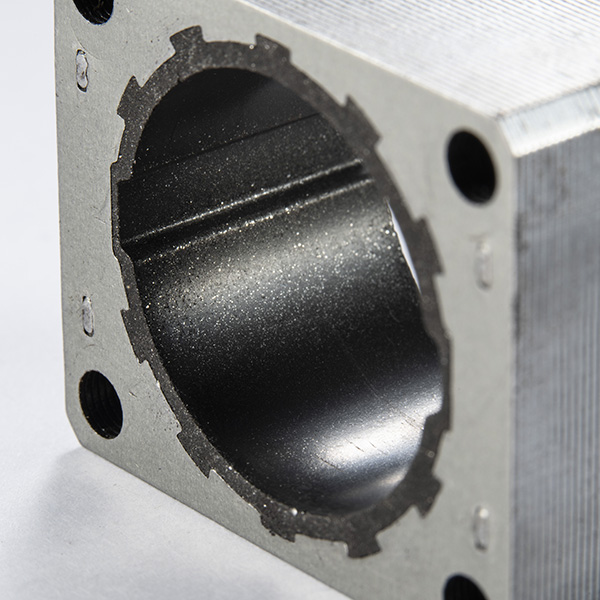

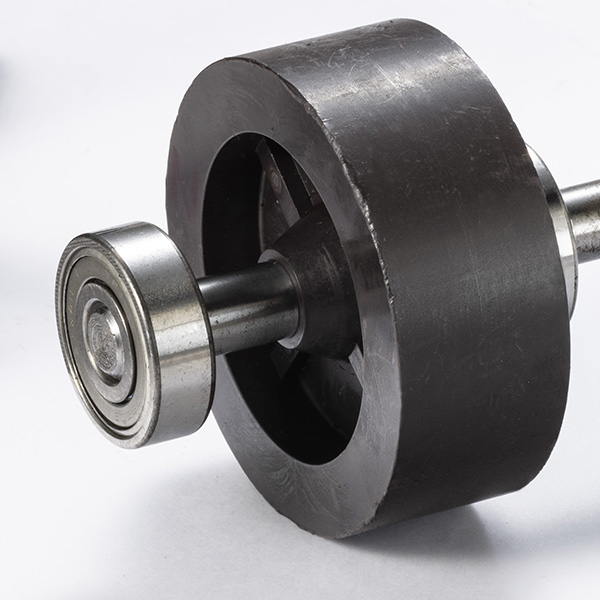

Integrally molded Shafts

This method is often used for rotating parts.

It reduces cracking and process of bonding in press-fits, which helps to improve product quality.

Integrated resin molding

Integral molding with resin is a good match and is suitable for complex shapes, weight reduction and standardization of magnetic parts.

However, careful selection of the component materials is to be required.

Integral molding with other magnets

We can provide assembly parts using sintered magnets and compression magnets, other than plastic mags.

Rare Metals

Those materials which can be procured in Japan, such as ferrite-based, neodymium-based and samarium-based, are available in all our plants, including one in China.

In addition to isotropic materials, we also specialize in forming magnetic field using anisotropic materials with high magnetic properties.

Rare metals are relatively easy to obtain high magnetic properties and are easy to use, but the demand is expected to increase further in the future due to recent price hikes.

We also recommend considering ferrite materials from cost-efficiency perspective.

Magnetic powder

We recycle and sell magnetic materials to make effective use of limited resources, reduce CO2 emissions and the environmental impact.

Other magnetic assemblies

The company has progressed to the production of plastic magnets by converting it into a recycling business, from the production of magnetic powder.

Plastic magnets have the advantage of being precise and complex in shape, however, their magnetic properties are lower than those of sintered magnets as they contain resin. In order to compensate, we assemble parts using sintered magnets, compressed magnets and rubber magnets.

We are working to make use of the knowledge and experience we have gained in magnetic materials and recycling into the assembly of other types of magnets.

Precision cutting parts

Plastic magnets can be integrally molded with shafts, pressed and cutting parts.

These are rarely used as stand-alone products, but are assembled with other components.

Our Shenzhen plant in Guangdong Province in China, is taking advantage of its geographical location to meet the demand for precision metal-cutting parts.

If you are looking for precision cutting parts of ferrous and non-ferrous materials in the µ order, please contact us. We are happy to assist you from prototyping to mass-production.