Manufacturing & Creating magnets and their components which are essential for a carbon-neutral society.

TESLAM Group is a company that contributes to the realization of "decarbonized society".

Our Mission and Values

- We are committed to provide our customers high quality, high-specification magnet-related parts that will benefit to the communities.

To this end, we listen to our customers' needs in detail, make proposals, and work together to contribute to the communities. - We "manufacture products” with lesser environmental load at the best of our ability.

For this purpose, we are working to shorten production time, review manufacturing processes and equipment, recycle and reuse unused or defective products. - Our responsibility is to our stakeholders such as customers, suppliers, employees, and other related parties, for them to be satisfied with a sense of accomplishment both spiritually and substantially.

We spend a lot of time on our work. Hence, our employees must have a sense of joy, fulfillment and purpose in their jobs, making the most of our precious time.

The products we make are only one component or one material, but we can enhance these products by having our customers make effective use of them.

Expanding the use of lightweight plastic mags can reduce carbon dioxide emissions.

We are committed to contribute to energy conservation, global environmental preservation, and effective utilization through our magnetic related business.

Plastic magnets

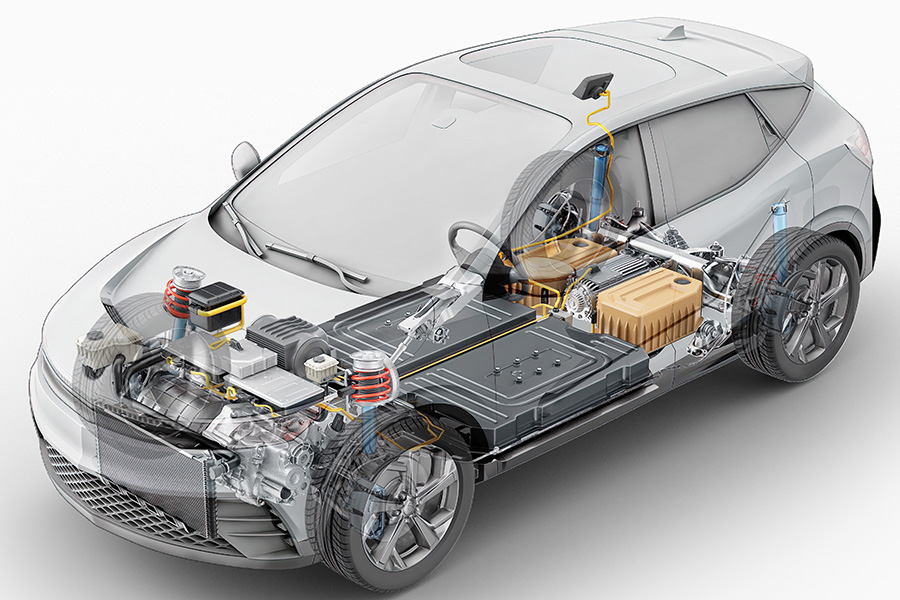

Motor Utilization

- DC brushless motors that use magnets, are highly efficient which allows for more efficient motor control by replacing them with these motors. (It is a known fact in the industry, the price of drivers and software has come down and it makes it easier to use DC brushless motors from a cost standpoint.)

- Reduction of manufacturing process: The adhesion process can be reduced by molding the magnet and shaft integrally.

- Designing efficient magnetization waveforms by magnetic field analysis allows efficient motor specifications which brings us lower power consumption.

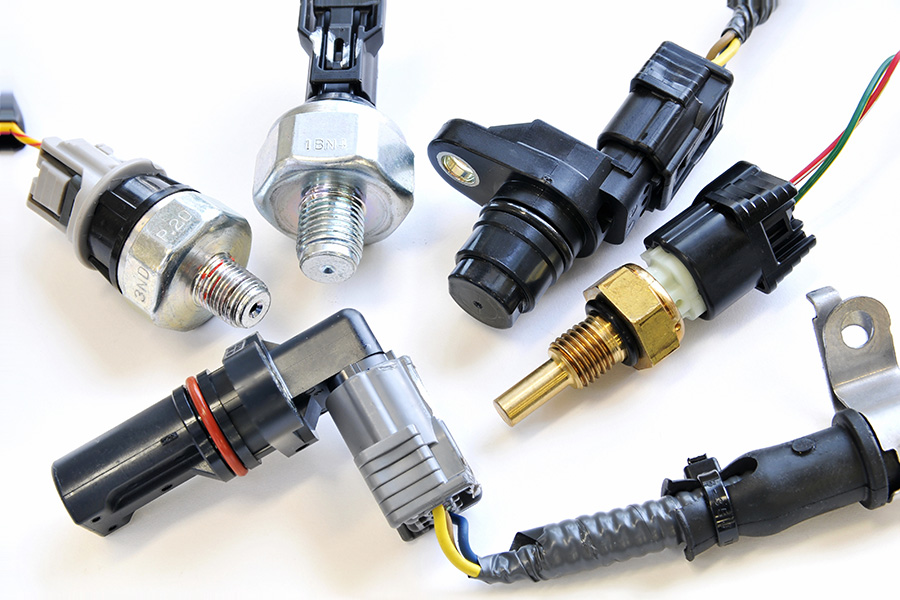

Sensor Utilization

- Detecting the position of rotating and moving devices and parts enables to reduce power consumption by controlling operations and minimizing unnecessary motion.

Motors and Sensors

- Lightweight compared to other types of magnets as the specific gravity (density) is lower.

Magnetic particle

We have been working on the recycling and reuse of ferrite sintered magnets since its operation followed by promoting the reuse of radio wave absorbers.

Why we join contributing to CO2 reduction :

- Eliminates the need for landfill disposal as industrial waste.

- Enables us the effective use of resources.

- Shorten the time for the manufacturing process of magnets and radio wave absorbers.