Flow from conception

to mass production.

Consultation

Tell us about your company requirements, we take your terms into consideration and reflect them in our proposal specifications and estimates.

Magnetic field analysis

Based on the customers' needs, we analyze the magnetic field to meet the required specifications and conditions in order to determine the materials and dimensions with the customer. We also propose materials and shapes for accompanying parts.

In addition, we also design the magnetic circuit of molds by performing magnetic field analysis.

Determine specifications

Prototype

We ask our customer to evaluate the performance of prototypes at the customers side, after we make them at minimal cost to suit the intended purpose through some tests by cutting the base material and/or by fabricating a prototype die.

Prototype mold fabrication

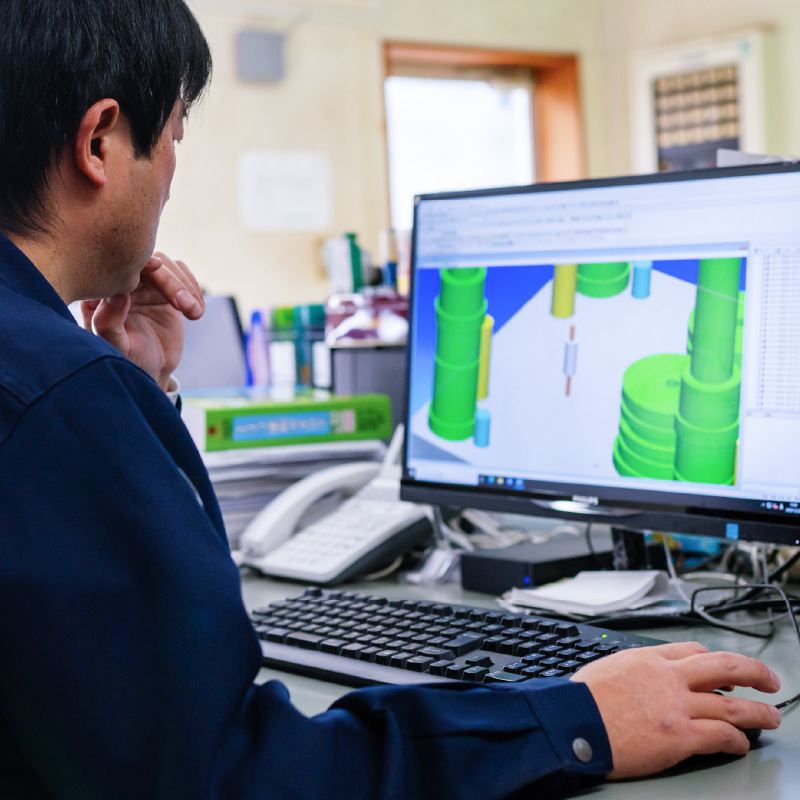

We use 3D CAD for mold to design with reliability the configuration of mold coma parts and magnetic circuits.

We design molds and jigs, and process them with in-house machine tools and outsource processing for assembly and adjustment.

Prototype and Evaluation

We perform prototype molding and post-processing using prototype molds.

We ask our customers to evaluate the prototypes in a variety of ways so that it is guaranteed that they meet the specifications before the delivery to the customer.

We work with the customer to change the specifications and design according to the evaluation results of the prototype to make it suitable for the market.

Mass production mold making

Mass production

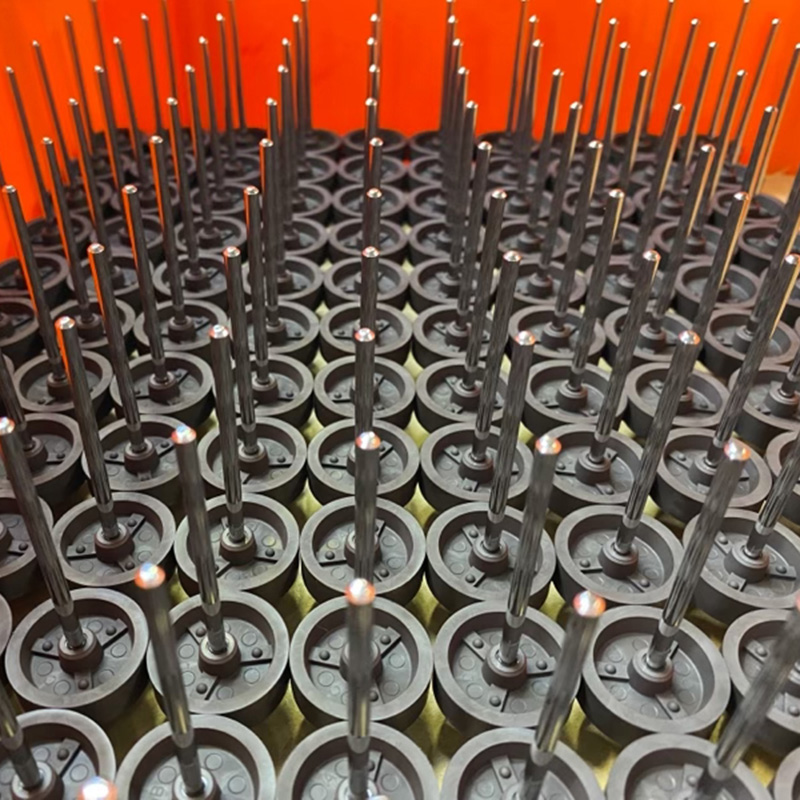

Based on the information gained during trial production, we will manufacture mass-production molds and proceed for production.

In order to utilize the experience gained from prototyping for mass production, we handle our customer requirements at our assembly-line production site from the conceptual stage.